|

|

Cold Plasma Technology in Ships

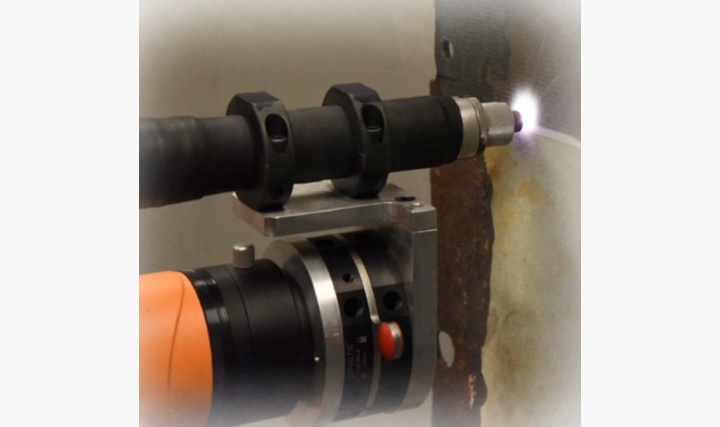

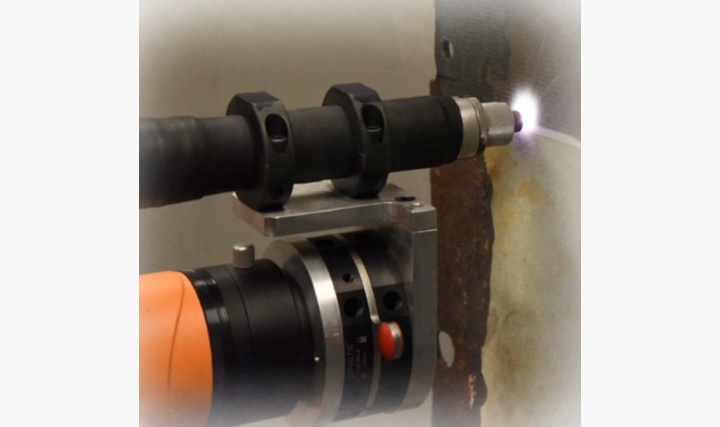

Dr. Seyed Hamed Pourrahmatikhalejan Cold plasma technology, also known as non-thermal plasma, has drawn extensive interest in a range of industries because of its distinctive characteristics and broad applicability. Cold plasma provides novel solutions for shipyard processes that improve efficiency, environmental acceptability, and operational performance. This literature review discusses the existing and future applications of cold plasma technology for shipyard processes. 1. Surface Preparation Coating removal and surface preparation is one of the major uses of cold plasma in ship repair yards. Conventional practices, like abrasive blasting, involve hazardous materials and produce large volumes of waste. Cold plasma technology offers a more environmentally friendly option through the use of an air plasma beam for the selective removal of coatings from substrates. This process not only minimizes environmental effect but also minimizes worker exposure to toxic chemicals, thereby improving employee safety [1-2].

Figure1. Surface preparation by cold plasma technology [2].

2. Air Quality Management

Shipyard industries are usually required to deal with emissions from ocean-going ships and industrial processes. Cold plasma technology is a powerful air cleansing solution. PlasmaGuard STAX™ Marine systems, for instance, are integrated into current exhaust systems to purify emissions up to 99.9% effective. This kind of integration meets the demands of strict environmental legislation and improves workplace health through the efficient elimination of contaminants [3].

3. Wastewater Treatment

Wastewater treatment is one of the major concerns in shipyard operations. Cold plasma technology has been identified as efficient, energy-saving, and green technology for wastewater treatment. Through the generation of reactive species, cold plasma has been found to degrade effectively various aqueous pollutants and inactivate water-borne pathogens, including viruses. The technology offers a non-thermal option to conventional wastewater treatment technologies, fulfilling environmental sustainability agendas [4].

![figure-3-wastewater-treatment-plasma-reactor-[5]-_136482.jpg](https://www.tersanedergisi.com/dokumanlar/tersane/328/figure-3-wastewater-treatment-plasma-reactor-[5]-_136482.jpg)

Figure 3. Wastewater treatment plasma reactor [5].

4- Odor Control and Air Pollution Reduction

Cold plasma technology has been used to improve odor control by breaking down harmful emissions prior to their release into the atmosphere.

This is a process that utilizes cold plasma reactors which destroy the pollutants by advanced oxidation and decomposition reactions and convert them into harmless byproducts such as water and carbon dioxide. These applications are especially useful in the upkeep of air quality standards and making the environment safer for shipyard workers. JOAAIRSOLUTIONS.COM 6. Cutting and Welding Applications Accuracy in welding and cutting is extremely crucial in shipbuilding. Plasma technology has been utilized in the elimination of temporary welded attachments, like stud weldments and lifting lugs. By using this process, operators can cut cleanly and quickly, flush to base material, with no preheat time and minimal extra surface grinding necessary. Accuracy and productivity provided by plasma cutting improve overall shipyard fabrication [6].

![figure-2-plasma-air-control-systems-[7]-_5404874.jpg](https://www.tersanedergisi.com/dokumanlar/tersane/328/figure-2-plasma-air-control-systems-[7]-_5404874.jpg)

Figure 2. Plasma air control systems [7].

Conclusion

The application of cold plasma technology in shipyard activities has several benefits, ranging from efficiency and eco-friendliness to increased safety. Regardless of whether the activity is surface preparation and coating removal or air and water purification, cold plasma provides multi-dimensional solutions to some of shipbuilding's and maintenance's most significant issues. As research and development in the area proceeds, it is expected that cold plasma solutions will become more central to contemporary shipyard activities.

References

1- https://www.dau.edu/sites/default/files/webform/documents/25546/DOD-AUG22-18621.pdf

2- https://www.sae.org/binaries/content/assets/cm/content/attend/2019/dod/2019-presentations/bo6-astolfi.pdf

3- https://plasmaguard.com/marine/

4- https://pmc.ncbi.nlm.nih.gov/articles/PMC8494511/

5- https://www.watermagazine.co.uk/2022/11/24/plasma-waters-launches-subsidiary-in-water-stressed-india/

6- https://joaairsolutions.com/blog/how-cold-plasma-improves-odor-control/

7- https://www.riedel-filtertechnik.com/en/exhaust-air-cleaning/odour-control/cold-plasma-technology

İlginizi çekebilir... Gemilerde Tankerlerde Gaz Serbest Bırakma (Gas Free) İşlemiSezer ASLAN

Yangın, Acil Durumlar Deprem Eğitim Uzmanı

Yangın Risk Analizi, Danışman, NFPA Member... ISPFIRE Sapfir Markalı Yangın Söndürme Modülleri ile Yat ve Liman Yangınlarına İlk MüdahaleÜlkemizde her yıl onlarca yat, limanda veya seyir esnasında farklı sebeplerle yanmaktadır. Bu istenmeyen durum, maddi zararların yanı sıra bazen can k... Koruma Fonksiyonlu Bir Yangın Pompasının Optimal Bir TasarımıYangından korunma, ulusal ekonomik ve sosyal kalkınmanın önemli bir parçasıdır, sosyalist piyasa ekonomisinin gelişmesinin vazgeçilmez bir garantisidi... |

|||

©2026 B2B Medya - Teknik Sektör Yayıncılığı A.Ş. | Sektörel Yayıncılar Derneği üyesidir. | Çerez Bilgisi ve Gizlilik Politikamız için lütfen tıklayınız.